Quality design, manufacturing and installation

We’ve got your construction project covered from start to finish.

Offering a comprehensive turn-key service, we can design, engineer, manufacture, and install your light steel gauge project from start to finish and ready to operate.

Our product range covers various structures, such as:

Trussed floor joists

Roof trusses

Residential framing (panels and trusses)

Commercial premises (warehouse, apartment, childcare centre, etc.)

Modular structures (pods, modular homes)

Facade framing

Cladding

Project Workflow

Consultation

Contact us to discuss your project scope. By understanding your design requirements in detail, we can provide a tailored solution and the best value quote for your project needs.

Design & Engineering

Send your existing documentations to us, or we can produce all necessary drawings you need. We may require to redesign your current structural engineering to adapt with LGS framing. Our certified engineers will provide all truss calculations to comply with relevant building codes and engineering specifications.

Detailing

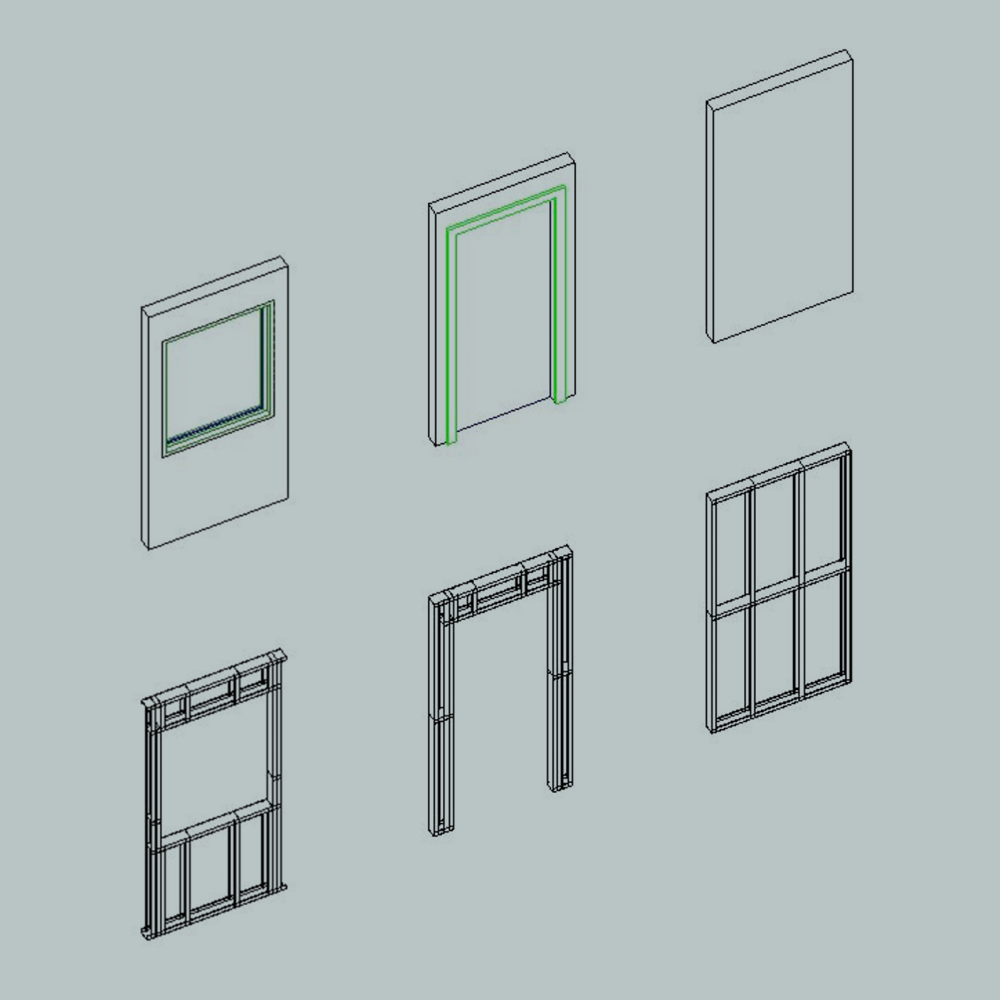

We can help you every step of the way to provide accurate structural detailing including shop drawings, bracing and fabrication layouts, truss and wall layouts with fixing locations and installation details. Frame enhancements can also be added according to your design criteria, such as extra studs for specific loads, cladding, mechanical clearances and non-structural products.

Manufacturing & Delivery

Once a rigorous review of our models and all council approvals are complete, we commence production on our cutting edge CNC roll-forming machinery. Sections are cut to length, including holes and notches for easy installation. Frames can be pre-assembled in the factory and delivered direct to your site.

Installation

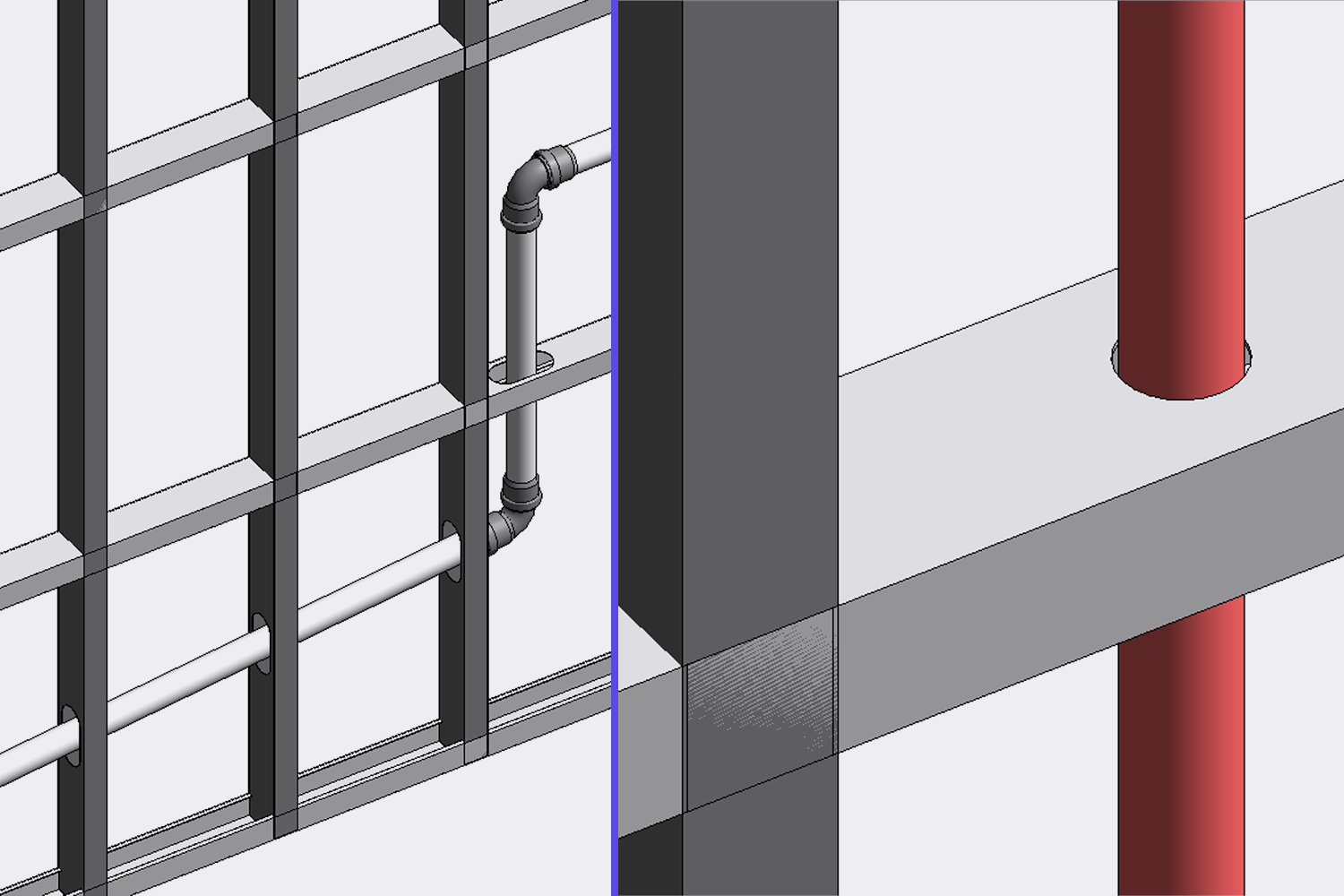

The most significant advantage of LGS framing, installation is simple to do on site with riveting guns and self-drilling fastener. With pre-punched studs in the panels, other trades can complete their job faster, such as wiring, cabling and plumbing installations. All you need left is a BBQ to wrap up the job!

Building a 3 toilet blocks within 4 hours including first floor. We also provide installation upon request.

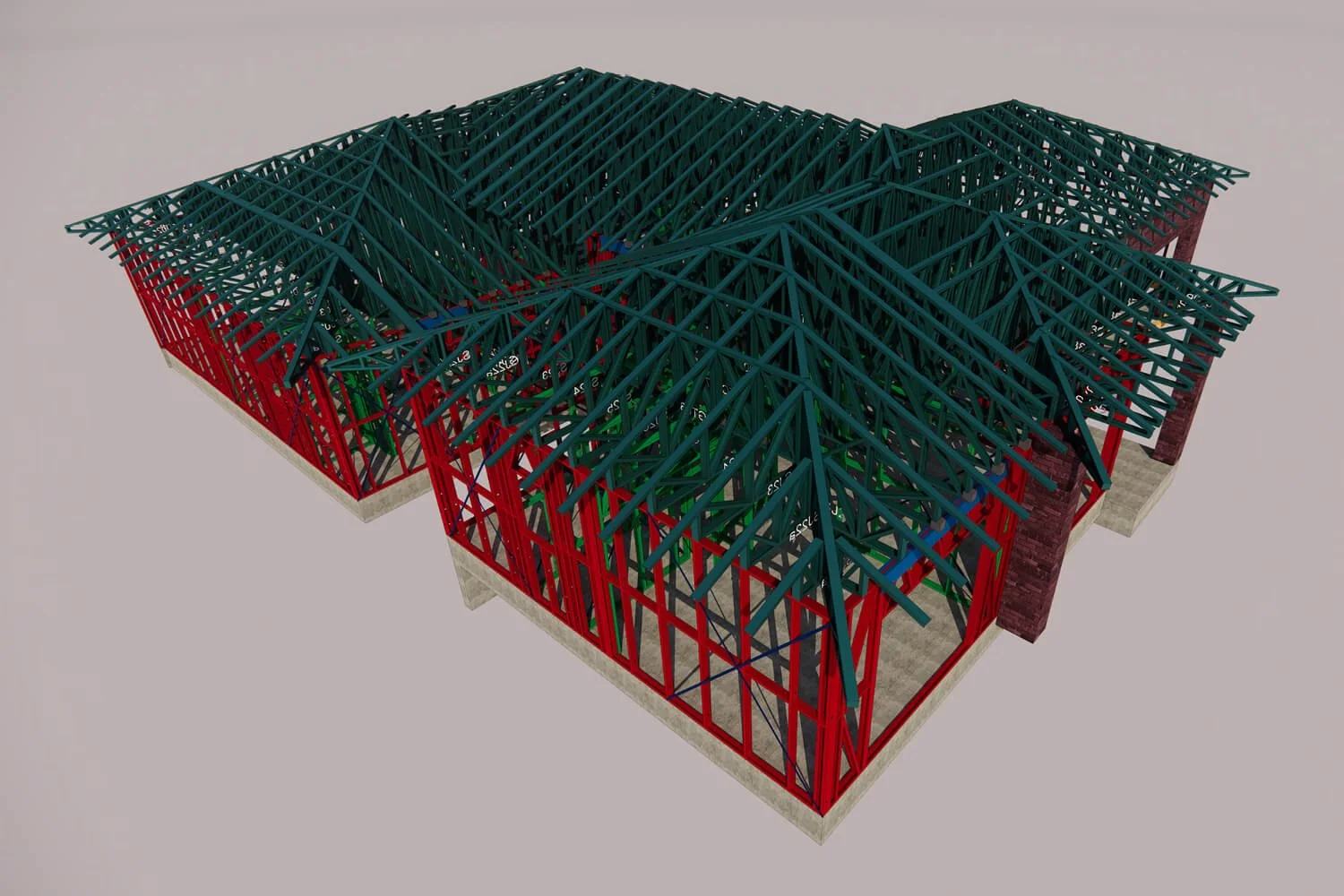

Residential roof structure

Bathroom pod

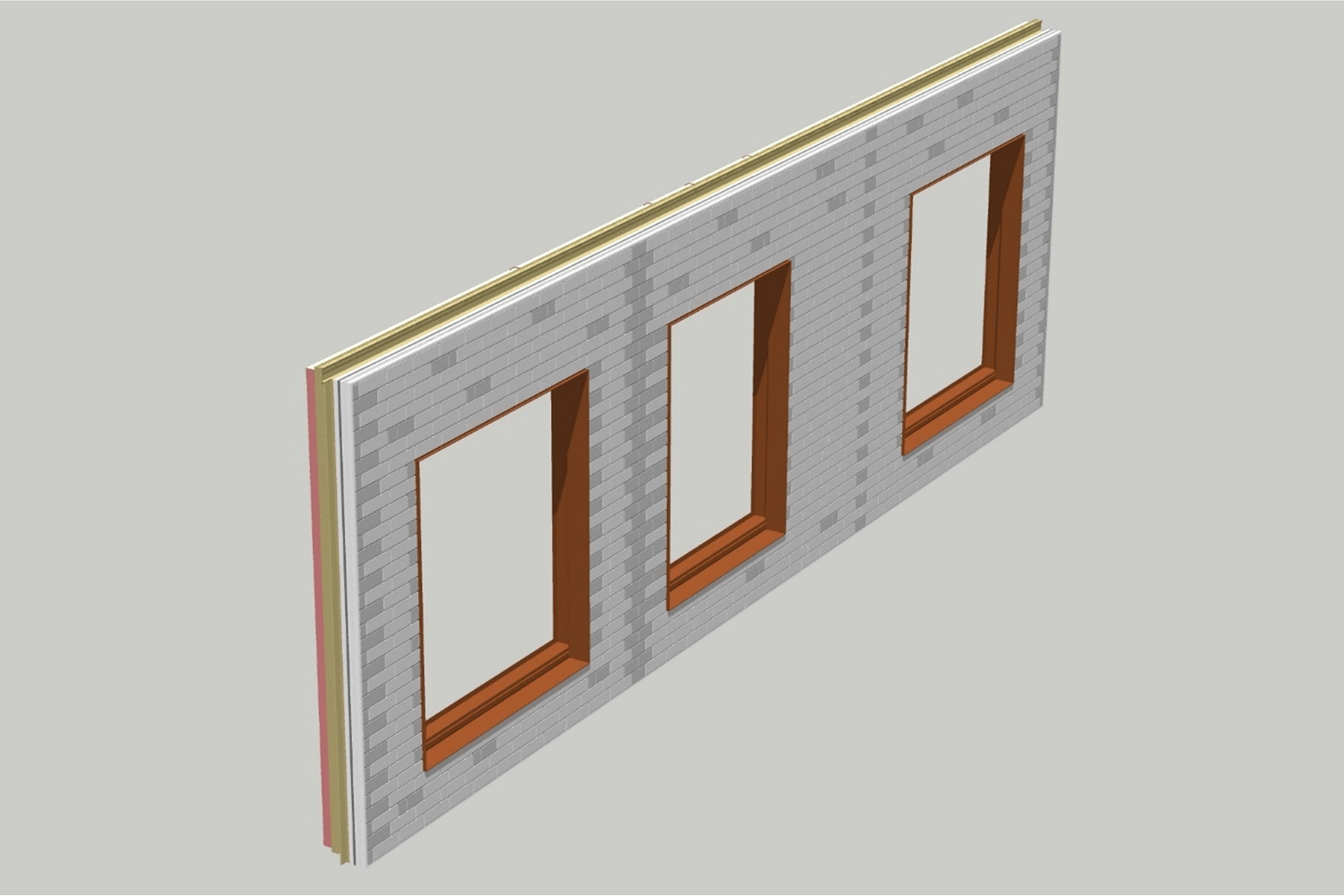

Facade panel

Truss frame with bracing

Bathroom pod

Roof truss

Structure

3D modelling / BIM

Wall panels

Frame penetration

Software Solutions

-

Building Information Management (BIM)

Our design BIM automation includes Revit and StrucSoft plug-in (MWF), with a specialised portal to efficiently manage the orders, design the workflow and secure the manufacturing, delivery and installation of the products.

Using the latest BIM softwares, we are also able to coordinate with your existing design files and adjust it to adapt with LGS framing. We put great value on collaboration with building designers to ensure potential issues are before manufacturing.

With our advanced modelling and workflow system, we can quickly visualise designs in 3D to our clients, maintain quality control, supervise time management within the project scope and minimise cost through wastage control.

-

Production line

We use Scottsdale CNC roll-former, the most advanced and top-of-the-line machine and production system for light gauge steel fabrication.

Within the integrated Scottsdale system, we utilise ScotSteel to interpret architectural designs into panels and truss engineering. Capable of handling complex designs, the powerful software can turn any structural element into panel assemblies with immense precision. Production files are exported seamlessly into ScotRF, the control software for the CNC roll-forming machines that can diagnose any anomalies in real time, allowing non-stop assembly with the highest quality.

Our sophisticated software solutions allow us to run designs on the roll-former machine almost instantly. These integrated systems ensure that we maintain the highest level of fidelity to the design, accuracy that minimises waste in both materials and time, and flexibility with regards to any potential adjustments and changes.

Not only is light steel framing widely considered as the future of construction in the world, it also offers better value for money in the long run.

As the the general public understands more about the advantages of using light steel framing, it is recognised in Australia as the top-tier construction material for safety and durability. With exceptional strength-to-weight ratio, superior structural integrity and versatile adaptability, light steel is the next generation of construction material.

With integrated software underlying its design and engineering, light steel framing is the most time-efficient choice for construction. High precision means less time and less material wasted. Read more to discover how you can benefit from light steel framing for your project.

Ready to build your vision?

We take quality light steel construction to the next level.